Pellets are not bullets, though they have many similarities. Most are obvious, they are lead, while most bullets are a harder lead mix. The problem is that every bullet mold ever made seems to end up being a pellet mold and while many may work fine, others do not. The three specific designs I want to talk about today are Boat-tails molds, Heeled bullet molds, and Gas-check molds. In a nutshell these three mold designs not only do not work for pellets, but they may also lead to gun jams and inaccurate shooting.

The first one of these that has no practical application for air guns is the Boat-tail bullet design. The Boat-tail’s claim to fame is a flattened trajectory, and greater energy transfer on impact, and they are best known for better resistance to wind deflection and air drag-related energy loss. I have been in the firearms arena way too long to remember my exact sources, but I want to give credit where credit is due, if memory serves I got a refresher on this topic a couple of years ago with a Guns and Ammo article and a couple of things I remember came from a great writer Phil Massaro and a test he did a few years back. Phil’s test took a practical approach and compare a flat-based bullet to a boat-tail design at long distances for accuracy. I am looking for the article, but I think at 250-300 yards there was only a .2” difference in accuracy and at 500 yards the difference was ½ inch.

By now you probably see where I am going with this. The more recent Guns and Ammo article built on this premise looking at the gas cloud when a flat bullet versus a boat-tail left the barrel. There is of course air in the barrel that gets compressed when a round is fired, but the boat-tail gas cloud was much larger, this could only be explained by gas bypassing the boat-tail bullet and enveloping the boat-tail bullet outside the barrel. This can lead to a variety of problems. In the case of a bullet fired from a rifle, this gas can still be at 10,000-15,000 psi so these pressure losses do not affect the velocity (This would not be the case with air rifles). More importantly, the flat-based bullet was faster out of the barrel. The flat base of a pellet provides a uniform surface for the pressurized air and the flat base or hollow skirt pellets will help the soft lead of the pellet to seal against the barrel better. For these reasons, I do not think it is wise to use pellets made from a boat-tail bullet mold.

While a heeled bullet has its place in firearms (Think 22LR), it makes little sense with pellet rifles. A heeled bullet has an inset on the base, the purpose of this is to create a smooth surface between the bullet and the brass of the bullet casing so they are the same basic diameter. The reason for this is a very long time ago most cartridges were rimmed and or rimfire cartridges. The creation of the heeled bullet made it easier to make gun barrels since it allowed for one diameter (One cut in the machining process). It provides no benefit for modern bullets or pellets and can lead to air pressure bypass and changes the Ogive dimensions (That will be another article).

While a Gas-check bullet may look like a heeled bullet, this is only because it has not been finished. When finished a gas-check bullet will have a small metal cap made of copper, zinc, or aluminum around the base of the bullet, making the side of the bullet uniform, not inset. The original purpose of the gas check was to keep gas bypass to a minimum to eliminate gas cutting and lead deposits in the barrels of Magnum pistols and rifle barrels. Again, this is not a factor in pellet rifles and we are not dealing with tens of thousands of PSI of super-heated gas. On top of that, every pellet I’ve seen that was popped out of a gas check mold is not sold with a gas check on it.

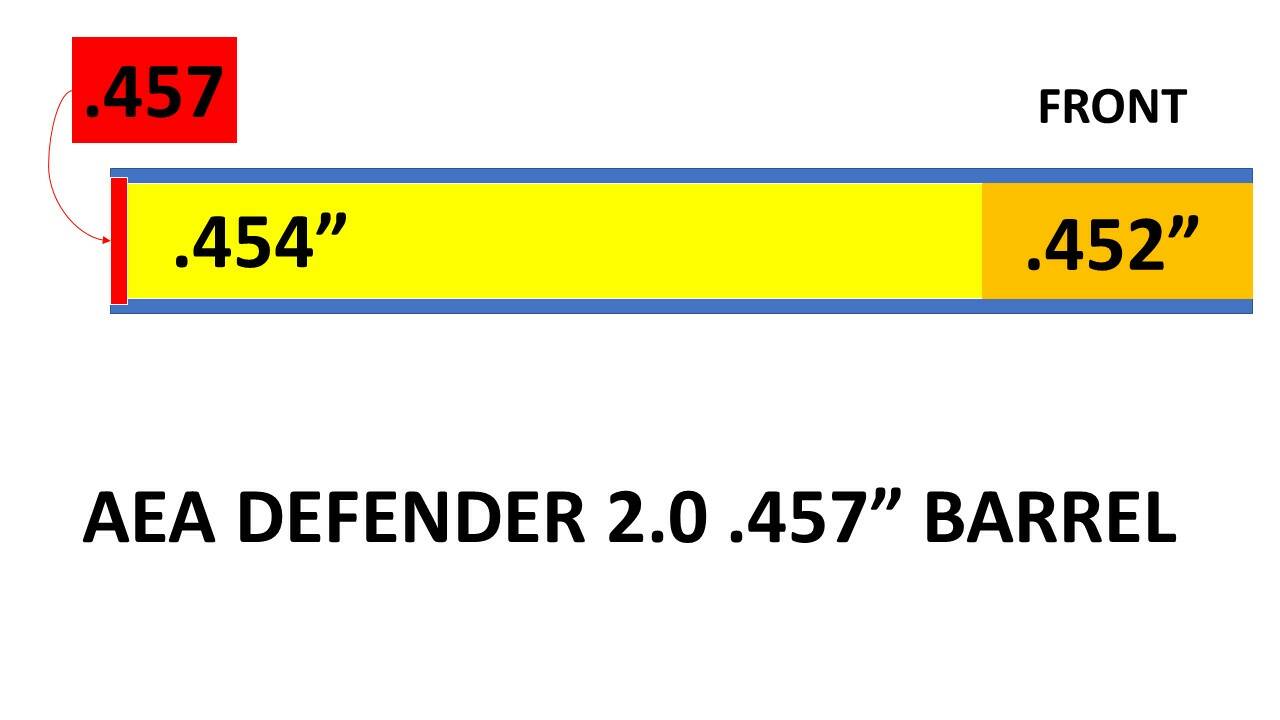

Folks, it is pretty simple, this market is growing exponentially and everyone with a lead pot and access to some old molds is now in the pellet business. Education and research are your friends. Spend the time to figure out what works and why it works. I would also toss out that many of the problems that are occurring with big-bore air rifles can be explained by bad pellet design (Use of tired, old bullet molds), the lack of proper pellet sizing, and the wrong lead alloy.

I have a saying that everyone I know hates hearing from me “Do the work”. With a bit of research, you will find most of my pellet designs on the pages of custom mold makers, even then I tweak the measurements before they are made and in many cases, they go to a second custom maker who creates hollow points for some and hollow skirts for others. In most cases, users have spent 750.00 or more for a big bore air gun, this is the wrong time to go looking for the cheapest pellet on the market that may or may not work in it.